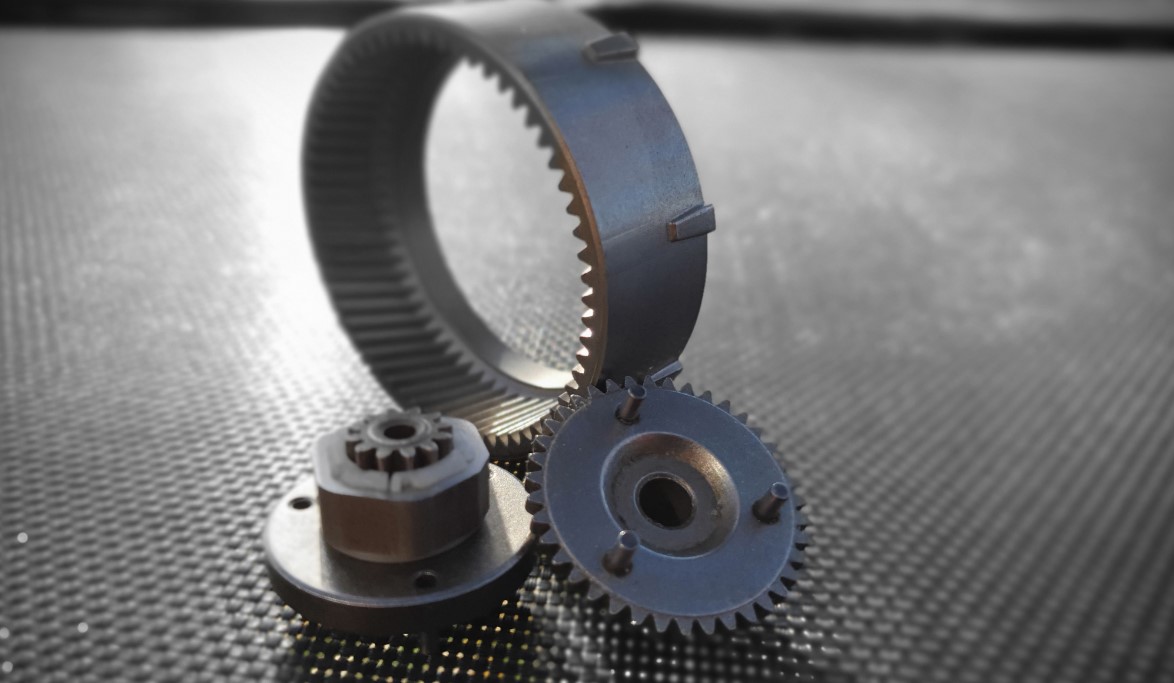

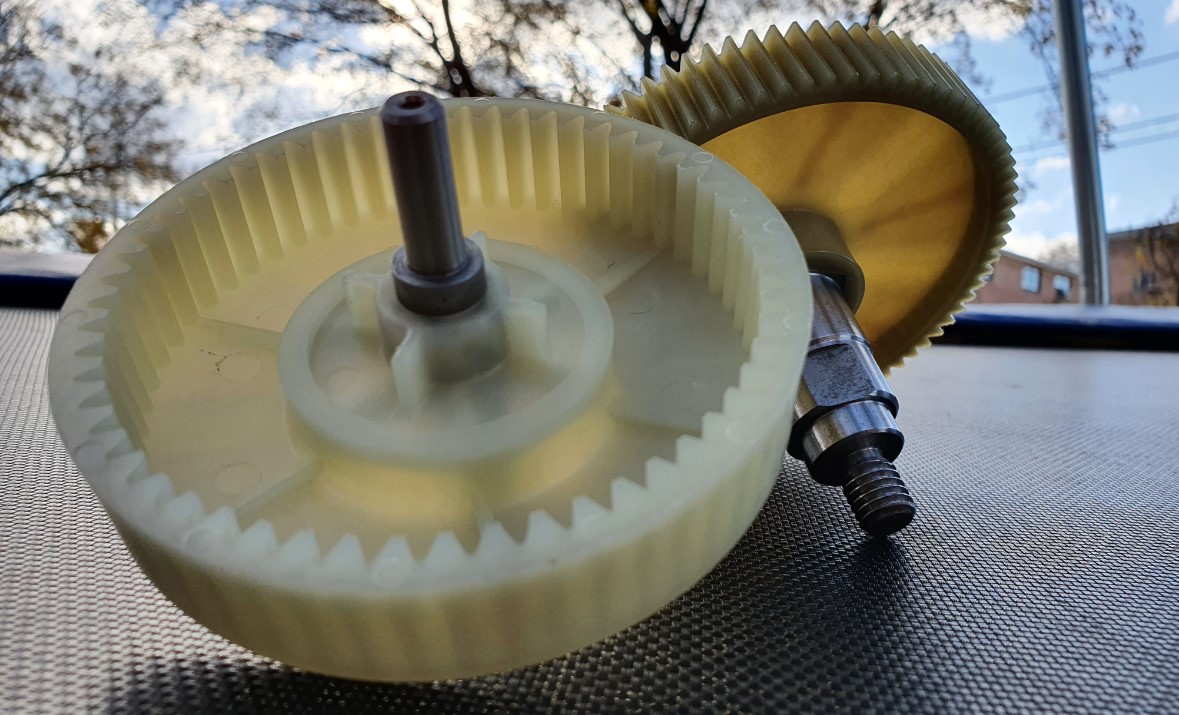

Plastic, Powder Metal Drivetrain Design:

MoldedGear LLC has innovative and over 25 years of experience of gearing to optimize the performance of molded polymers, those resulting improved gears that are stronger, quieter, lighter, and more efficient than traditional plastic gears. Our engineering team has a strong understanding of plastic and powder metal gear design. The material selection uses scientific principles to robust respectable design. Our gear design analysis is in combination with 3D solid modeling to provide optimization of involute or cycloid gear geometry. We also recommend coring system, and specify the effect of fillers and gate placements.

Given your gear requirements, we can review your preliminary concept, and optimize the gear proportion and material selection. We can complete prototype or production drawings, including gear profile or solid models. We will focus on a solution that gives you the most cost-effective, durable, and efficient design. Our goal is create the highest possible molded gear quality and tolerance. The design review will provide the recommend coring system and specify the effect of fillers and gates placements.